Fiber optic infrastructure is no longer just a connectivity choice it is a strategic, long-term investment that defines the performance and resilience of industrial networks. From factory floors and rail systems to power utilities and intelligent surveillance, fiber must deliver speed, reliability, and stability in environments where failure is not an option.

One of the earliest and most impactful decisions in any fiber deployment is the choice between multimode and single-mode fiber. While both technologies move data at the speed of light, their behavior over distance, tolerance to interference, scalability, and cost profiles differ significantly especially under industrial conditions.

This guide examines multimode and single-mode fiber through a practical, industrial lens. Rather than focusing on theoretical limits or office-based use cases, it highlights the real-world considerations that matter most when designing, upgrading, or future-proofing industrial fiber networks.

Fiber Optics in Industrial Networks

Industrial environments place unique demands on network infrastructure. Electrical noise, high voltage equipment, physical distance, and environmental exposure make copper cabling unreliable or impractical in many scenarios. Fiber optics address these challenges by providing immunity to electromagnetic interference, electrical isolation between devices, and the ability to transmit data over long distances without signal degradation.

Fiber is commonly used in industrial networks to connect switches across facilities, extend Ethernet connectivity to remote equipment, support IP-based surveillance, and integrate legacy serial devices into modern networks. Because fiber cabling is often difficult and expensive to replace once installed, selecting the correct fiber type at the outset is essential.

Multimode Fiber in Industrial Deployments

Multimode fiber uses a larger core that allows multiple light paths to travel through the fiber simultaneously. This design enables high data throughput over relatively short distances, making multimode fiber suitable for localized industrial applications.

In industrial settings, multimode fiber is most often used inside buildings, control rooms, and factory floors where network distances are limited and conditions are relatively controlled. It works well for connecting switches within a production area, linking equipment racks, or supporting high-bandwidth communication over short runs.

One reason multimode fiber is frequently selected for these applications is cost. Optical components for multimode systems are generally less expensive, which can reduce initial deployment expenses. However, this cost advantage diminishes when networks expand beyond their original design, as multimode fiber is inherently limited in distance and scalability.

Single-Mode Fiber in Industrial Deployments

Single-mode fiber is engineered with a much smaller core that allows light to travel in a single path. This reduces signal dispersion and attenuation, enabling data transmission over significantly longer distances with greater signal stability.

In industrial applications, single-mode fiber is widely used for backbone infrastructure, outdoor installations, transportation corridors, energy facilities, and large-scale surveillance systems. It excels in environments where equipment is geographically dispersed or where network expansion is expected over time.

Although single-mode optical components typically have a higher upfront cost, the fiber itself offers exceptional longevity and scalability. As bandwidth demands increase, single-mode fiber can support higher data rates without the need to replace the installed cabling, making it a preferred choice for long-term industrial infrastructure.

Multimode vs Single-Mode: What Actually Matters

When comparing multimode and single-mode fiber for industrial use, theoretical specifications are less important than real-world performance and planning considerations.

Multimode fiber is best suited for short-distance applications within contained environments. Its limitations become apparent as distances increase or when network expansion is required. Single-mode fiber, on the other hand, is designed for long distances, outdoor environments, and future scalability.

The most important differences revolve around distance capability, long-term bandwidth support, environmental suitability, and lifecycle cost. While initial hardware pricing may influence decisions, industrial networks benefit most from solutions that minimize future redesigns and infrastructure replacement.

Choosing the Right Fiber for Industrial Applications

Selecting the appropriate fiber type begins with understanding how and where the network will operate. Distance is often the most decisive factor. If communication links remain within a building or production area and are unlikely to grow, multimode fiber may be sufficient. For connections between buildings, along roadways, or across large industrial campuses, single-mode fiber provides greater flexibility.

Environmental conditions must also be considered. Outdoor exposure, temperature variations, and electrical interference favor single-mode fiber due to its consistent performance over long runs. Indoor, controlled environments offer more flexibility, but scalability should still be considered during the planning stage.

Another critical consideration is future expansion. Industrial systems rarely remain static. Adding new cameras, controllers, or network segments is common, and choosing single-mode fiber early can reduce upgrade costs by eliminating the need to replace cabling as bandwidth demands grow.

Environmental and Reliability Considerations

Industrial networks are expected to operate continuously under challenging conditions. Vibration from machinery, exposure to moisture or dust, and temperature extremes can all impact network reliability if not accounted for in the design.

While both multimode and single-mode fiber are resistant to electromagnetic interference, single-mode fiber is more commonly deployed in harsh or outdoor environments due to its superior distance performance and lower attenuation. Proper cable selection, robust connectors, and industrial-grade enclosures are essential to ensure reliability regardless of fiber type.

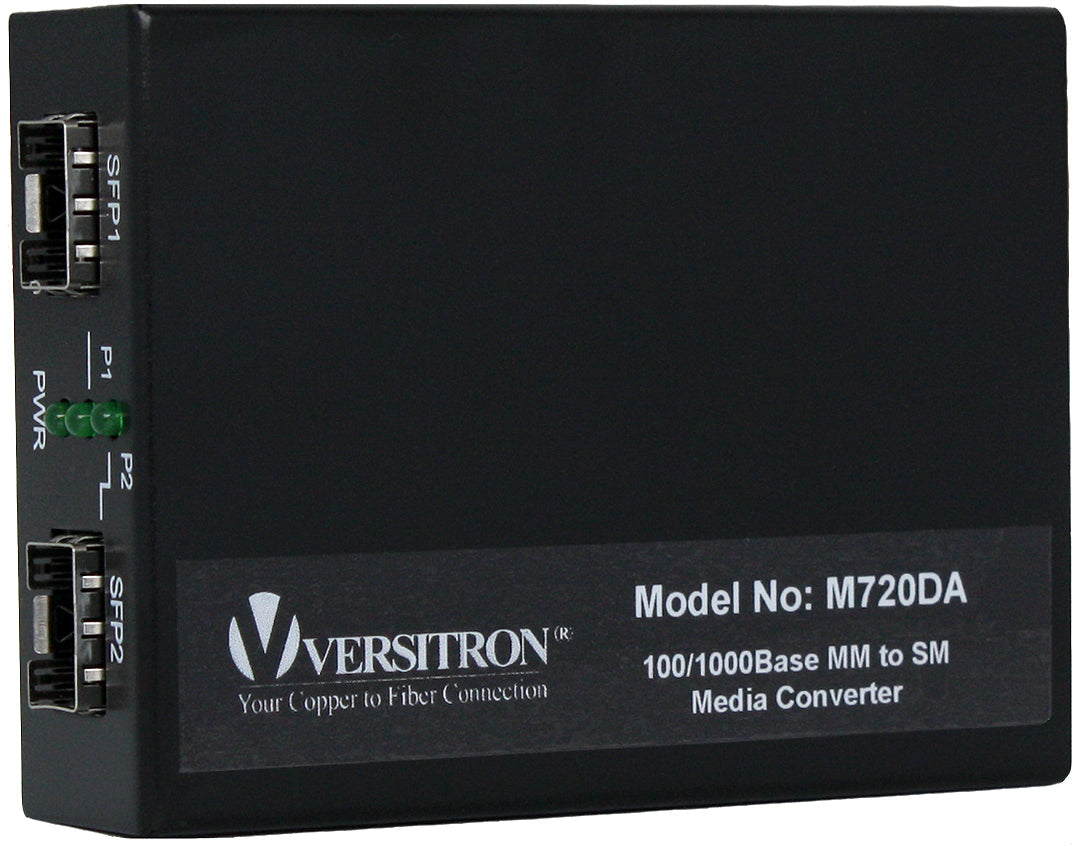

Compatibility with Industrial Networking Equipment

Fiber selection is closely tied to the networking equipment used in an industrial deployment. Media converters, industrial Ethernet switches, SFP modules, and serial-to-fiber devices must all support the selected fiber type. Equipment with modular optical interfaces offers greater flexibility, allowing network designers to adapt to changing requirements without replacing core hardware.

In many industrial networks, fiber is used to bridge Ethernet or serial communication far beyond the physical limits of copper cabling. Choosing the correct fiber type ensures seamless integration with existing infrastructure while enabling reliable operation across extended distances.

Common Planning Mistakes in Fiber Selection

One of the most common mistakes in industrial fiber planning is selecting multimode fiber for applications that later require longer distances or outdoor expansion. Another frequent issue is underestimating future bandwidth needs, leading to unnecessary upgrades and downtime.

Failing to account for environmental conditions can also compromise network reliability. Fiber selection should always be part of a comprehensive network design that considers equipment compatibility, installation quality, and long-term operational goals.

Conclusion

There is no universal solution when choosing between multimode and single-mode fiber for industrial applications. Multimode fiber can be effective for short-range, indoor deployments with limited expansion requirements. Single-mode fiber provides the performance, scalability, and reliability required for long-distance, outdoor, and mission-critical networks.

By evaluating distance, environment, and future growth at the design stage, industrial network planners can build fiber infrastructures that remain reliable and adaptable for years to come.